You probably understand the significance of selecting trustworthy cable protection if your work requires consistent electrical power in challenging conditions. In many situations where round cables were formerly the norm, advances in flat cable technology have significantly increased the viability and dependability of flat cables. Over circular cables, flat cables have significant performance-enhancing and technical advantages.

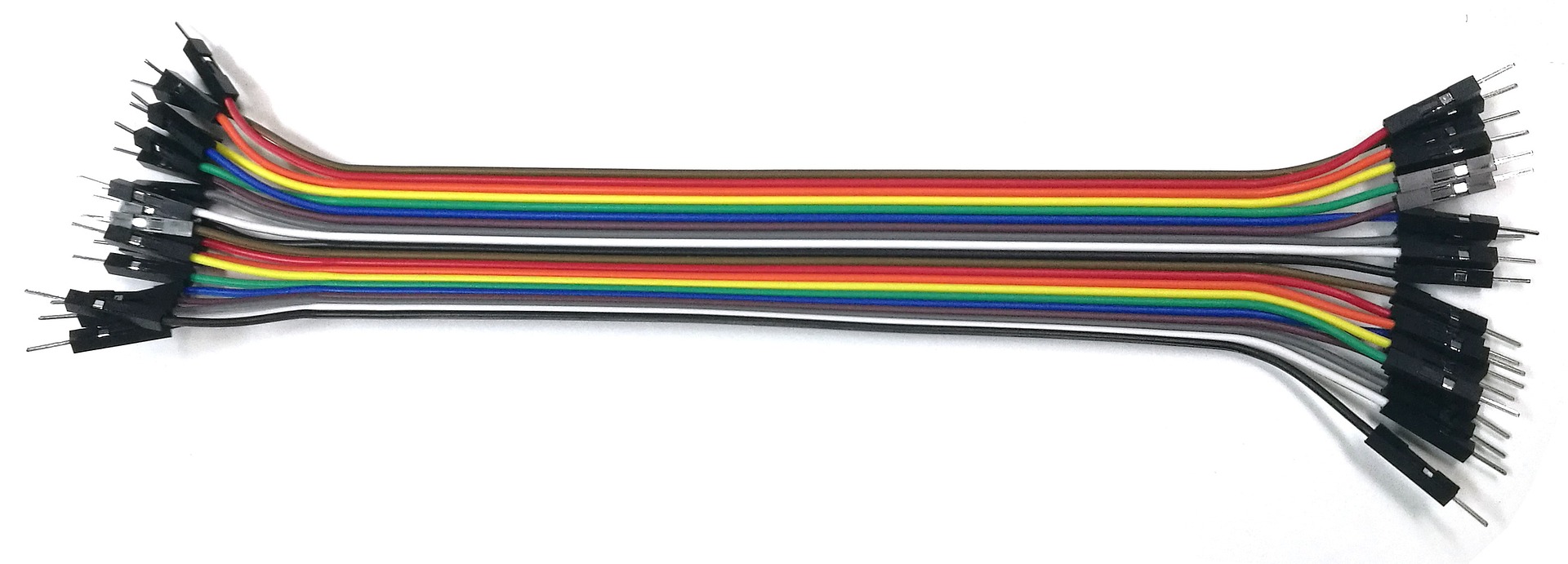

A flat cable is a flat wire created by connecting many wires. This cable is inexpensive, lightweight, and strong and works well in large and small equipment. The flat electrical cable is resistant to cold, acid, alkali, heat, and radiation, among other things. It is between -40°C and 70°C outside. The fundamental components utilized to connect various gadgets are cables. The most popular cables on the market are flat cables. The soaring demand in the aerospace sector was a major factor in the design of these cables. Take a look at six noteworthy benefits of using flat cables.

1. Reliable and Space Efficient

One can eliminate many typical causes of wiring mistakes and malfunction through the simplicity of flat cable and its parallel conductor layout. The conductors are registered one-to-one with the terminating connector or board, making assigning the right contacts nearly automatic.

Flat cables can be made smaller physically by removing extra insulation, fillers, and tapes. Additionally, because of their low profile, they may hug surfaces and utilize small or underutilized spaces. You can layer or stack them with nearly little dead space between them when they have a rectangular cross-section, and this results in the highest conductor density possible for a given volume. You can click here on a flat extension cord to get hold of the best flat cables.

2. Flexible With Consistent Electrical Characteristics

Any application requiring motion, including robots, axis-controlled industrial machinery, and automated medical diagnostic equipment, needs flexibility. The bend radius of the flat cable is less than that of ordinary round cables because conductors are parallel and aligned in a flat plane. Conductors in a round cable may kink or “corkscrew” under repeated bending cycles, which shortens cycle life and increases the likelihood of failure. A flat cable can withstand 15 million flex cycles. Flat cable can offer a superior alternative for applications where significant flex cycling occurs, and short bend radii are present.

Electrical properties, including capacitance, impedance, inductance, crosstalk, time delay, and attenuation, are consistent since the conductor spacing is set and the cable’s shape is constant. Flat cables are more effective at dispersing heat than round cables because they have a larger surface-to-volume ratio. Because of this, a given temperature rise and conductor cross-section may support a greater current level.

3. Better Handling Capacity, Lightweight

Different conductors, such as shielded and unshielded for signal and power, as well as twisted pairs and single conductors, are mixed in one flat cable. This is due to the flat cable’s ability to reduce the number of distinct conductors to be managed, resulting in better organization and handling.

Due to its superior mechanical strength, the flat cable arrangement’s use of big conductors for strength is unnecessary. And you do not need excessive insulating materials like tapes and fillers.

4. Simple and Stronger

Flat cables often feature clear jackets and parallel conductors, which makes it easy to identify the conductors for quicker termination at the ends. Flat cables are, therefore, simple to fix.

Finally, the parallel construction of flat cables, as opposed to the asymmetrical load distribution in round cables, preserves the equal distribution of stress and loads. Therefore, consider adopting flat cables if you require a small and highly dependable design.

Flat cables have a larger surface-to-volume ratio than circular cables, and they can remove heat more effectively thanks to this increased ratio. This permits a greater current level for a specified conductor cross-section and given temperature rise.

5. Convenient Design

In contrast to round cables, flat cables often do not contain filler and shielding layers. Because the shield will not maintain its flat shape and eventually round out, attaching one to a flat wire might be challenging. Consequently, providing electromagnetic interference (EMI) protection is difficult using conventional shielding.

Flat cables are comparatively small for the number of connections they have since they often do not contain fillers or other materials. For this reason, they are flexible and stack well.

However, flat wires’ thin, elongated form might make their design unsuitable with a specific machine or panel holes. Businesses interested in employing flat cables should make sure they are compatible first.

6. Versatility and High-Density Interconnections

Since they are more flexible, flat cables have a wide range of applications. Thanks to their flexibility, they can quickly adapt to various forms, sizes, and combinations. They are perfect for many applications since they can bend and twist without breaking.

Only two directions provide easy bends in a flat cable wire. Due to this quality, these cables are widely sought-after for applications requiring significant bending and twisting during lengthy wire lengths, particularly raceways or conduits.

Due to the high wire-to-cable cross-sectional density, the flat cable may achieve a higher cabling density than traditional cable. Compared to round cables, layers of flat cable are more efficiently packed for higher conductor density.

The conductors’ precise physical and electrical length and a continuous and uniform dielectric reduce time delays between signals inside a particular flat cable.

Conclusion

These advantages are built into flat wire and are generally not understood by the typical design engineer. Although flat cable is not always necessary, it is more than just conductors in a different shape. They offer a collection of qualities that can address several design problems. Flat cables are easier to use, stronger, and simpler to repair. A flat cable’s parallel conductors evenly distribute all stresses and strains, making the cable considerably stronger and longer lasting.

Thanks for reading and y’all stay dandy.

-Diego

Follow me on Instagram and Pinterest for more menswear inspiration.

(Some of these links may contain affiliate links, so that means if you click and buy something, I get a cut. It helps keep the site going! Full Disclosure)